Why Medical Grade Nitrile Gloves Matter in Clinical Settings

Medical grade nitrile gloves are the gold standard for healthcare professionals who need reliable barrier protection without latex allergy risks. Here's what sets them apart:

Key Features of Medical Grade Nitrile Gloves:

- FDA-cleared for medical use with strict quality standards

- Latex-free synthetic rubber (no Type I allergy risk)

- Superior puncture resistance compared to latex or vinyl

- Chemical resistant to common disinfectants and bodily fluids

- AQL 1.5 or lower (Acceptable Quality Level for defects)

- Tested for viral penetration and barrier integrity

When to Choose Medical Grade vs. Industrial Grade:

- Medical Grade: Patient care, examinations, surgical procedures, lab work

- Industrial Grade: Janitorial tasks, automotive work, food service

Medical grade gloves undergo rigorous FDA testing and must meet ASTM standards like D6319 for exam gloves. They're designed specifically to protect both healthcare workers and patients from cross-contamination and bloodborne pathogens.

The difference isn't just marketing. Medical grade gloves have lower defect rates, stronger barrier protection, and consistent quality that matters when patient safety is on the line.

I'm Adam Schuh, President and CEO of Clinical Supply Company, where I've spent years working with dental professionals to source medical grade nitrile gloves that meet the highest FDA and ASTM compliance standards. My focus has been on bringing practitioner-tested solutions—like our accelerator-free EZDoff® line—that protect both your team and your patients without compromise.

The Anatomy of a Medical Grade Glove: Standards and Safety

When you use medical grade nitrile gloves, you're trusting them with your health and your patient's safety. This trust is built on a foundation of rigorous standards, exhaustive testing, and regulatory oversight. The journey from raw material to certified medical glove is complex, with the FDA requiring manufacturers to prove their gloves can meet the real-world demands of healthcare. For an overview of how medical gloves are regulated in the United States, see the FDA's page on medical gloves and the Wikipedia article on medical glove.

ASTM standards are the backbone of this testing. ASTM D6319 is the specification for nitrile exam gloves, setting requirements for tensile strength and barrier integrity. For chemotherapy drugs, gloves must meet ASTM D6978, which tests for resistance to permeation. This ensures that when chemicals or pathogens meet your glove, they stop there.

A critical measure is the Acceptable Quality Level (AQL), which measures the rate of pinhole defects. For medical grade nitrile gloves, the AQL must be 1.5 or lower, indicating a minimal defect rate. This is significantly stricter than industrial gloves, which often have an AQL of 2.5 or higher.

Beyond pinholes, these gloves undergo viral penetration testing to block bloodborne pathogens, puncture resistance testing, and chemical resistance testing against common disinfectants. Every aspect of barrier protection is scrutinized. We know these details matter for your daily practice, and you can learn more in our article on nitrile glove awareness.

What Makes Medical Grade Nitrile Gloves Different from Industrial Grade?

The difference between medical and industrial grade gloves is fundamental. Medical grade gloves must earn FDA 510(k) clearance, proving they are safe and effective for patient care, a step industrial gloves skip. The lower AQL of 1.5 or less for medical gloves means higher manufacturing precision and a lower defect rate—essential when handling blood samples or performing procedures. Intended use defines the product. Medical gloves are engineered for healthcare settings with exposure to bloodborne pathogens, while industrial gloves are made for janitorial, automotive, or food service tasks and lack the same rigorous testing for biological hazards.

How Gloves Protect Healthcare Professionals and Patients

Medical grade nitrile gloves act as a shield, protecting you from patient-borne pathogens and preventing you from cross-contaminating patients. They break the chain of infection by creating a physical barrier microorganisms cannot cross. This cross-contamination prevention is vital for immunocompromised patients and for ensuring you don't take workplace pathogens home. Protection against bloodborne pathogens like Hepatitis B, C, and HIV is a primary function. The chemical-resistant, puncture-resistant, and watertight properties of nitrile create a reliable barrier against these dangers. By reducing infection transmission, gloves are a cornerstone of aseptic technique and contribute to public health, as we explore in our article on how advanced gloves are redefining hygiene in dentistry.

Nitrile vs. The Alternatives: A Clear Winner for Clinical Use

The three main disposable glove options are nitrile, latex, and vinyl. While each is used in various industries, for clinical use, medical grade nitrile gloves consistently outperform the alternatives. Their unique combination of safety, durability, and performance makes them the go-to choice for healthcare facilities.

Here's how these three materials compare across the factors that matter most in your practice:

| Feature | Nitrile Gloves | Latex Gloves | Vinyl Gloves |

|---|---|---|---|

| Durability/Puncture Resistance | Superior; excellent tear resistance | Good; can tear/puncture more easily | Poor; least durable, tears easily |

| Allergy Risk (Type I & IV) | Very Low (Type IV possible, but preventable with accelerator-free) | High (Type I allergy to natural rubber proteins) | Very Low (no latex proteins) |

| Chemical Resistance | Excellent; resistant to many chemicals, oils, solvents | Good; can degrade with certain chemicals | Poor; limited chemical resistance |

| Tactile Sensitivity | Excellent; modern formulations offer high sensitivity | Excellent; known for "second skin" feel | Fair; can feel bulky, less sensitive |

| Cost-effectiveness | Moderate; durable, fewer changes needed | Moderate to Low; often cheaper per box, but allergy risk | Low; cheapest per box, but frequent changes needed |

The evidence speaks for itself. If you'd like to explore this topic further, we've written extensively about why nitrile outperforms latex in terms of allergies, durability, and compliance.

The Superiority of Nitrile

The superiority of medical grade nitrile gloves comes from their synthetic rubber composition. Made from acrylonitrile and butadiene, they are completely latex-free, eliminating the risk of Type I latex allergies for both staff and patients. Nitrile also excels in performance, offering high tensile strength and superior puncture resistance that outpaces both latex and vinyl. This durability means fewer mid-procedure glove changes, improving efficiency. Modern formulations also provide excellent memory and fit, conforming to your hand for a "second skin" feel without sacrificing protection. For a balanced perspective, check out our article on nitrile gloves: benefits and drawbacks to know.

Understanding Latex and Vinyl Limitations

It's also important to understand why latex and vinyl fall short in clinical settings. Latex gloves, while comfortable, pose a significant risk of natural rubber latex allergies (Type I), which can be severe. This risk to both healthcare workers and patients has led many practices to abandon them. Vinyl gloves, while inexpensive and latex-free, offer major compromises. They have lower chemical resistance and a higher puncture rate than nitrile. Furthermore, vinyl's poor fit and dexterity make them feel bulky and ill-suited for precise clinical work. While the initial cost is low, their lack of durability and performance makes them a poor choice for most healthcare tasks. For a detailed comparison, our article on nitrile gloves vs. other gloves: key differences is an excellent resource.

Selecting the Perfect Medical Grade Nitrile Glove for Your Practice

Finding the right medical grade nitrile glove isn't about grabbing the first box on the shelf. Your needs vary depending on the task, from delicate procedures to instrument sterilization. Understanding key features—thickness, texture, fit, and special formulations—makes the decision straightforward. The right glove can transform both safety and efficiency in your practice. For a comprehensive look, explore our guide on choosing the right high-quality glove for you.

Glove Thickness (Mils): Balancing Protection and Dexterity

Glove thickness, measured in mils, is a balance between protection and dexterity.

Lighter gloves (3-4 mil) offer exceptional tactile sensitivity, perfect for detailed procedures where feeling every contour is critical. They provide adequate barrier protection for routine tasks but are less durable for heavy-duty use.

Mid-range gloves (5-6 mil) are the workhorse for most dental practices, balancing good tactile sensitivity with solid puncture resistance. They are ideal for everyday exams and general patient care.

Heavy-duty gloves (8+ mil) provide maximum protection for handling sharp instruments or harsh chemicals. The trade-off is reduced tactile sensitivity, making them better for sterilization tasks than intricate clinical work.

Texture, Fit, and Tactile Sensitivity

Details like texture and fit directly impact safety and efficiency. Most nitrile gloves feature textured fingertips or surfaces to improve grip in wet conditions, preventing instrument slips. A proper fit is also non-negotiable. Gloves that are too large reduce dexterity, while gloves that are too tight cause hand fatigue and can tear. It's crucial to use a sizing chart to find the right fit for each team member. Finally, tactile sensitivity—the ability to feel through the glove—is essential for precision work. Modern nitrile formulations offer excellent feedback even in durable, protective gloves, reducing hand fatigue and improving control.

Sterile vs. Non-Sterile: When to Use Each

Understanding when to use sterile versus non-sterile gloves ensures the appropriate level of protection.

Sterile gloves are individually packaged and required for surgical procedures and other invasive treatments where introducing microorganisms could cause infection. This includes implant placements, biopsies, or any work in an aseptic field.

Non-sterile gloves are clean, come in dispenser boxes, and are perfect for the vast majority of dental tasks. This includes routine exams, non-invasive procedures, and general clinical tasks where a barrier is needed but a sterile field is not. They are more cost-effective for high-volume use.

Innovations: The Rise of Accelerator-Free Gloves

A key innovation in medical grade nitrile gloves is the development of accelerator-free options. While standard nitrile eliminated Type I latex allergies, the chemical accelerators used in manufacturing could sometimes trigger Type IV hypersensitivity (contact dermatitis), causing redness, itching, and blistering. Accelerator-free nitrile gloves are made without these chemicals, offering a skin-friendly formulation that dramatically reduces the risk of this delayed allergic reaction. These gloves are a game-changer for professionals with sensitive skin, providing the same high-level barrier protection, puncture resistance, and tactile sensitivity without the irritation. Learn more about the benefits of accelerator-free nitrile gloves and see why they are increasing in popularity.

Best Practices: Proper Glove Use from Donning to Disposal

Even the best medical grade nitrile gloves are only effective when used correctly. Proper technique is just as important as product quality. Every step, from donning to disposal, plays a critical role in infection control and keeping your team and patients safe.

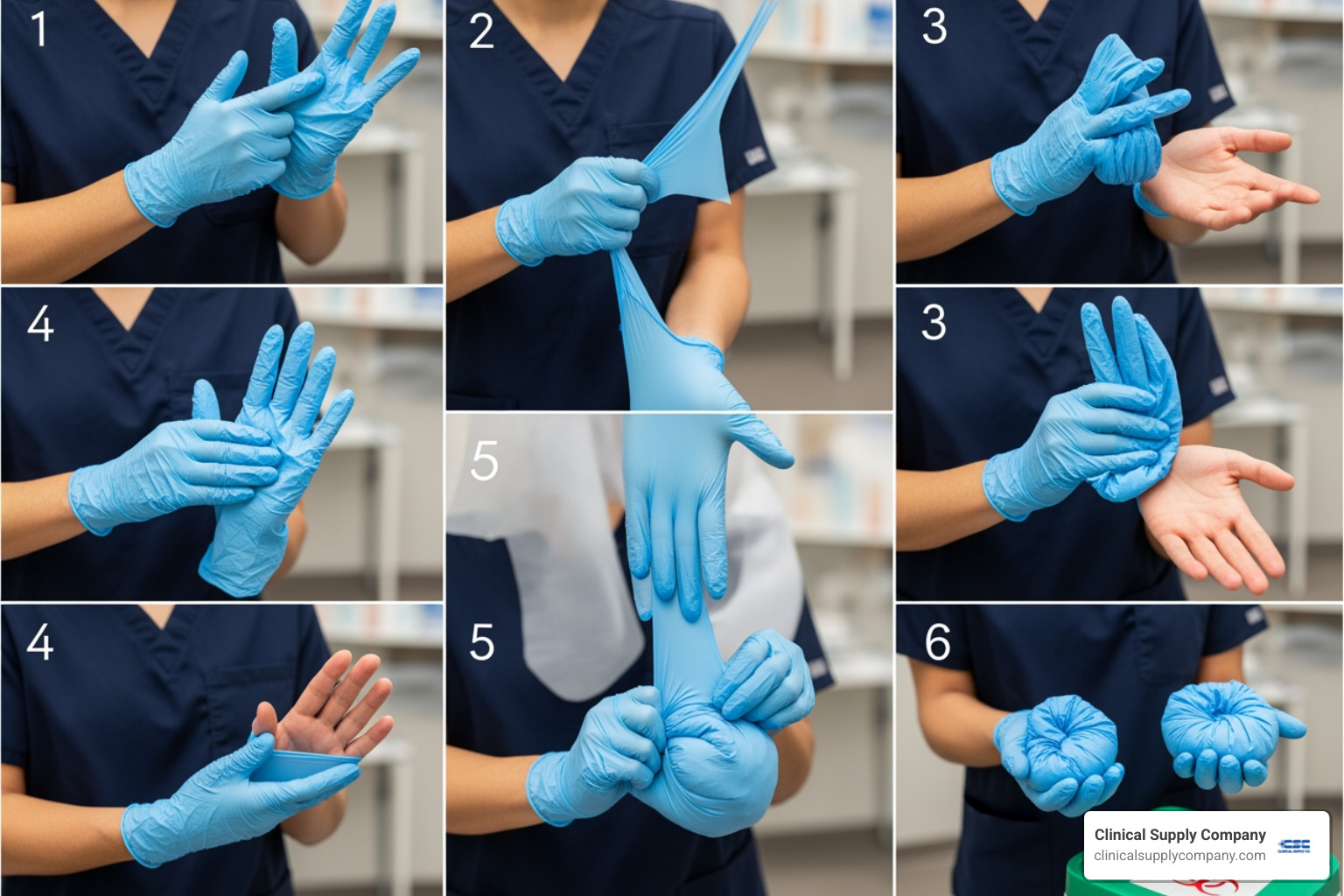

The Correct Procedure for Donning and Doffing Gloves

Following CDC guidelines for donning and doffing prevents contamination.

Donning (Putting On): Always start with clean hands, washed with soap and water or sanitized. Select the correct glove size and inspect for defects. Pull the first glove on by the cuff, then use your gloved hand to pull on the second, avoiding contact with your bare skin. Ensure the cuffs cover your wrists.

Doffing (Taking Off): This is a critical step to avoid contamination. Use the glove-in-glove technique. With one gloved hand, pinch the outside of the opposite glove at the wrist and peel it off, turning it inside out. Hold the removed glove in your still-gloved hand. Then, slide your bare fingers under the cuff of the remaining glove and peel it off, enveloping the first glove. Dispose of the bundle immediately in a biohazard container and wash your hands. Our EZDoff® gloves are designed to make this process smoother, as explained in the science behind EZDoff gloves.

Storage and Disposal for Safety and Integrity

Proper storage and disposal are essential for maintaining glove quality and ensuring safety.

Storage: Most medical grade nitrile gloves have a shelf life of three to five years when stored correctly. Keep them in their original packaging in a cool, dry place away from heat, direct sunlight, and fluorescent lighting, as UV rays and high temperatures can degrade the material and compromise barrier protection.

Disposal: Used gloves are contaminated waste and must be disposed of in designated biohazard containers. This protects waste handlers and the public from exposure to infectious materials. While most nitrile gloves are not biodegradable, proper medical waste disposal ensures they are handled safely.

Frequently Asked Questions about Medical Grade Nitrile Gloves

We hear from dental professionals and healthcare providers across the Midwest every day, and certain questions about medical grade nitrile gloves come up time and again. We're always happy to help clarify, because informed choices lead to better protection for everyone in your practice.

Can you be allergic to nitrile gloves?

Yes, though it's rare and different from a latex allergy. Medical grade nitrile gloves eliminate the risk of Type I latex allergies (immediate, severe reactions). However, a small number of users may experience Type IV hypersensitivity, a delayed contact dermatitis. This is not a reaction to nitrile itself, but to chemical accelerators used in manufacturing. Symptoms include redness, itching, and dry skin. The solution is to use modern accelerator-free nitrile gloves, which are formulated without these chemicals. If you or your team experience irritation, switching to an accelerator-free option is the best path forward. Learn more in our guide to prevent allergic reactions with accelerator-free exam gloves.

Are colored nitrile gloves stronger than standard blue ones?

No, the color of a medical grade nitrile glove has no bearing on its strength, thickness, or quality. The color is simply a dye added during manufacturing. A black glove is not inherently tougher than a blue one. What matters are the specifications: mil thickness, AQL rating, and ASTM compliance. However, color can be useful for organizational purposes (e.g., different colors for different tasks or sizes) or for spotting punctures when double-gloving, as a tear in the outer glove will reveal the different color of the inner glove.

What does "chemo-tested" or "chemo-rated" mean?

This designation means the medical grade nitrile gloves have been specifically tested for resistance to permeation by chemotherapy drugs, following the ASTM D6978 standard. The test measures the breakthrough time—how long it takes for a hazardous drug to pass through the glove material. A longer breakthrough time means better protection. These gloves are essential for anyone handling chemotherapy drugs or other hazardous medications, as required by standards like USP <800>, to protect them from repeated chemical exposure.

Conclusion: Partnering for Uncompromised Safety and Supply

Throughout this guide, we've walked through what makes medical grade nitrile gloves the trusted choice for dental and healthcare professionals. Their latex-free composition eliminates allergy concerns. Their superior puncture and chemical resistance keeps your team safe. Their adherence to strict FDA and ASTM standards ensures consistent, reliable barrier protection. These aren't just features on a spec sheet—they're the reasons why nitrile has become the gold standard in clinical settings across the Midwest and beyond.

When you choose medical grade nitrile gloves, you're making a commitment to quality that protects both your team and your patients. Every procedure, every examination, every patient interaction deserves that level of care. But quality products are only part of the equation. Consistent supply matters just as much. We've all seen what happens when supply chains falter—practices scrambling for alternatives, compromising on quality, or facing shortages that disrupt patient care.

That's where Clinical Supply Company comes in. We're a Midwest company, based right here in Ohio, and we understand the challenges you face. We've built our business on being more than just a vendor—we're your partner in maintaining the highest standards of safety and hygiene. Our commitment goes beyond stocking shelves. We work tirelessly to ensure a reliable supply chain so you never have to worry about running out of the essentials that keep your practice running smoothly.

We offer practitioner-tested solutions that we stand behind, like our accelerator-free EZDoff® line, designed specifically to address real-world challenges in infection control and user comfort. These are products we've developed with your needs in mind, not just what's available from the biggest distributor. We believe in offering superior value without the markup you'd find at larger chains like Henry Schein or Benco Dental, where service often takes a backseat to volume.

Whether you're looking to stock up smart with wholesale nitrile and dental gloves or want to dive deeper into the role of quality gloves in infection control, we're here to support you every step of the way. Let's work together to create an environment where precision and protection go hand-in-hand, where your team feels safe, and where your patients receive the best care possible—every single day.

![Smile Brighter: Strategies for Seamless Dental Practice Management [Updated Dec 2025]](http://clinicalsupplycompany.com/cdn/shop/articles/0fa6b0579e40927029105c5067f1ed3080130066_{width}x.jpg?v=1764769664)